CATENARY

At the beginning of year 2013 another railway line with newly build catenary with the TRANSCOM’S products was completed. Designed and developed in conjunction with Bulgarian and foreign companies and experts, the parts and assemblies manufactured by TRANSCOM’S allowed setting new speed record on railroad in Bulgaria of 175km/h! For the needs of the railway infrastructure TRANSCOM’S produces and delivers: |

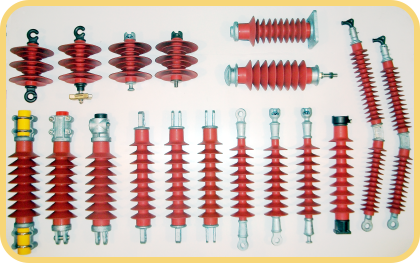

INSULATORS

In the manufacturing process, all fitting elements (respectively the insulators containing them) are subjected to 100% control with test loads as defined by TSRI 007-2006 and EN 50119. The NRIC is using more than 7 000 pcs of insulators manufactured by TRANSCOM’S since 2004, including in extreme climate environment, soiling and operational overloads. There is no registered failure of a composite insulator manufactured by TRANSCOM’S as of to-date. The multi-component technology chosen by TRANSCOM’S ensures flexibility in the manufacture of various designs and meeting the client-specific requirements. The selection of dimensions and V-shaped fixing of cable terminals to the fiberglass rod provide for unsurpassed mechanical strength of the insulators even in the unavoidable cases of prolonged electric arch in real circumstances (due to atmospheric and operational overloads). |

CANTILEVERS

TRANSCOM’S offers two solutions for the hanger pipes:

With view of the technical end economic studies, TRANSCOM’S recommends, as optimal solution, aluminium alloy F31 pipes and fixture of hot dip galvanized, precision cast steel. Using the wide range of fixing elements that TRANSCOM’S produces makes possible any other choice of materials for the pipes of the hanger constructions. |

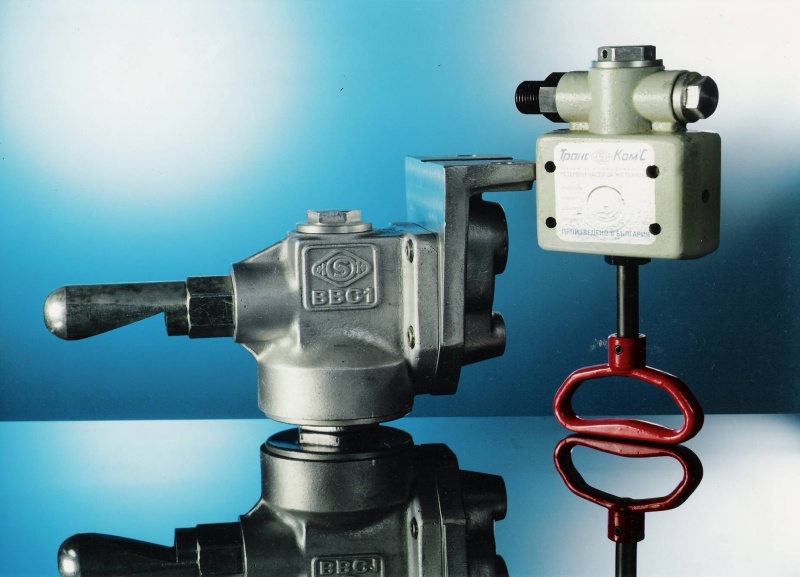

TENSIONING DEVICES

To respond to the specific needs of the NRIC, TRANSCOM’S company designed and developed a tensioning device for simultaneous compensating of the elongation of both the contact and the messenger wires. The tensioning devices of this type significantly reduce the cost of the tensioning system, with still guaranteed tensioning force, and assured protection of the line when tearing of one or both the contact and messenger wires occur. |

CLAMPS

|

CONCRETE WEIGHTS

TRANSCOM’S products range also includes concrete weight of 25kg, diameter of 410mm and height of 80mm. Thus reducing the total size of the weights-block, a longer travel of the tensioning device is provided. The new manufacturing technology allows producing of weights with height of 40mm and weight of 12,5kg. |

FIXTURE, TENSIONERS AND ADDITIONAL PARTS

|

ROLLING STOCK

TRANSCOM’S specialization in metal, rubber and rubber-to-metal parts of different size (0,001kg to 20kg) and versatile production program (single parts to mid-range mass production) provides good conditions for developing and manufacturing of wide variety of parts and systems in the rolling-stock trend. We have already developed a large range of elements and assemblies for the needs of our modern wagon-building partners. This allows us the flexibility to provide short lead times for small and large orders. The integrated quality system ensures that the requests of our customers are met with the attention to the detail required by the railway car/locomotive building industry.

As a manufacturing specialists focused in the railway industry, we will always consider developing/adopting new products for our customers in the railroad field, that suit our manufacturing capabilities.

Some of our most wanted products for the rolling-stock building industry of both passenger and freight railway cars/wagons include, but are not limited to:

RUBBER AND RUBBER-TO-METAL CUSHIONS AND COVERS

|

||||||||||||||||

PNEUMATIC EMERGENCY BRAKE ACTIVATOR

|

||||||||||||||||

SOLUTIONS FOR PASSENGERS WC

|

||||||||||||||||

FIXTURE AND PARTS FOR WAGONS

|

Since 1990-th TRANSCOM’S produces and supplies all the wagon-repairment and wagon-building factories in Bulgaria, and also multiple European companies, with high-quality spare parts, repairment sets and testing equipment for the air-brakes of the rolling stock.

Since 1990-th TRANSCOM’S produces and supplies all the wagon-repairment and wagon-building factories in Bulgaria, and also multiple European companies, with high-quality spare parts, repairment sets and testing equipment for the air-brakes of the rolling stock.

For planned and accidental repairments of function valves and specific pneumatic systems, TRANSCOM’S manufactures precise rubber, rubber-to-metal, klingerit and polymer parts, amongst which are full repairment sets and single parts for:

For planned and accidental repairments of function valves and specific pneumatic systems, TRANSCOM’S manufactures precise rubber, rubber-to-metal, klingerit and polymer parts, amongst which are full repairment sets and single parts for: Thanks to the long carrier of TRANSCOM’S founder – Dr. Angel Stefanov – as an university professor in the field of rolling-stock air brakes, and the many high-qualified specialists that work in the company, TRANSCOM’S has designed, developed and built multiple test stands for the unique needs of various domestic and foreign railway companies, including BDZ-Koncar, Metropoliten – Sofia, INTER-MEHANIKA – Serbia.

Thanks to the long carrier of TRANSCOM’S founder – Dr. Angel Stefanov – as an university professor in the field of rolling-stock air brakes, and the many high-qualified specialists that work in the company, TRANSCOM’S has designed, developed and built multiple test stands for the unique needs of various domestic and foreign railway companies, including BDZ-Koncar, Metropoliten – Sofia, INTER-MEHANIKA – Serbia. For more than 30 years TRANSCOM’S designs and offers its products for the railways to the domestic and the foreign markets. For the purposes of catenary overhaul and repair works TRANSCOM’S has provided thousands of tensioning devices, insulators, concrete weights, clamps, cantilevers, fittings and other parts, while at the same time participates in projects of building new catenaries in conjunction with leading builders in the branch – Dupnica – Kulata, Krumovo – Parvomay, Svilengrad – Turkish border, Danube bridge 2 etc.

For more than 30 years TRANSCOM’S designs and offers its products for the railways to the domestic and the foreign markets. For the purposes of catenary overhaul and repair works TRANSCOM’S has provided thousands of tensioning devices, insulators, concrete weights, clamps, cantilevers, fittings and other parts, while at the same time participates in projects of building new catenaries in conjunction with leading builders in the branch – Dupnica – Kulata, Krumovo – Parvomay, Svilengrad – Turkish border, Danube bridge 2 etc. All types of TRANSCOM’S insulators are manufactured by using high quality HTV silicone, epoxy-fiber glass rods and hot galvanized steel fittings – products of European companies – leaders of their branches. The types and dimensions of these elements are typical and interchangeable with those used by the NRIC until now and are in conformity with all regulations and specific requirements defined in the TSRI 007-2006.

All types of TRANSCOM’S insulators are manufactured by using high quality HTV silicone, epoxy-fiber glass rods and hot galvanized steel fittings – products of European companies – leaders of their branches. The types and dimensions of these elements are typical and interchangeable with those used by the NRIC until now and are in conformity with all regulations and specific requirements defined in the TSRI 007-2006. TRANSCOM’S cantilevers are identical by constructive dimensions with the operating in the NRIC’s overhead lines ones. They are produced by hot dip galvanized steel fixture and the material of the pipes depends on client’s choice. All the connective elements are similar and entirely interchangeable with the currently used fixture in the whole electrified railroads grid of the NRIC (7,000 km), which is aimed to conform to the requirement of reducing the diversity of elements by TSRI 007-2006.

TRANSCOM’S cantilevers are identical by constructive dimensions with the operating in the NRIC’s overhead lines ones. They are produced by hot dip galvanized steel fixture and the material of the pipes depends on client’s choice. All the connective elements are similar and entirely interchangeable with the currently used fixture in the whole electrified railroads grid of the NRIC (7,000 km), which is aimed to conform to the requirement of reducing the diversity of elements by TSRI 007-2006. For more than 10 years the TRANSCOM’S company produces tensioning wheels . Up to now in the overhead contact line of NRIC are mounted more than 2700 pcs patented by TRANSCOM’S tensioning wheels. The devices have passed many tests for compliance with both standard EN50119 and the technical requirements of NRIC (TSRI 007-2006). During the years of operation there is no registered failure – neither at static load, nor when event that activates the blocking mechanism occurred (tearing of a contact or messenger wire). The combination of aluminum wheel and dip-zinc coated steel fixture assures both strength and easy mounting.

For more than 10 years the TRANSCOM’S company produces tensioning wheels . Up to now in the overhead contact line of NRIC are mounted more than 2700 pcs patented by TRANSCOM’S tensioning wheels. The devices have passed many tests for compliance with both standard EN50119 and the technical requirements of NRIC (TSRI 007-2006). During the years of operation there is no registered failure – neither at static load, nor when event that activates the blocking mechanism occurred (tearing of a contact or messenger wire). The combination of aluminum wheel and dip-zinc coated steel fixture assures both strength and easy mounting. The fittings and fixing elements and clamps manufactured by TRANSCOM’S are fully compliant with the requirements of item 5.6.5 of the TSRI 007-2006.

The fittings and fixing elements and clamps manufactured by TRANSCOM’S are fully compliant with the requirements of item 5.6.5 of the TSRI 007-2006. The weights manufactured by TRANSCOM’S have passed many tests to comply with the normative documents and standards required. Conforming the parameters mentioned at TSRI 007-2006 and thanks to the precise geometrical dimensions and the lock-jointing, the concrete weights of TRANSCOM’S impart stability and the right finish to the tensioning system.

The weights manufactured by TRANSCOM’S have passed many tests to comply with the normative documents and standards required. Conforming the parameters mentioned at TSRI 007-2006 and thanks to the precise geometrical dimensions and the lock-jointing, the concrete weights of TRANSCOM’S impart stability and the right finish to the tensioning system. Each individual catenary project requires many joining, stabilizing and others unique parts. The versatile manufacturing capabilities of TRANSCOM’S are capable to meet the needs of developing and producing non-standard solutions in acceptable terms for building or repairment of a catenary.

Each individual catenary project requires many joining, stabilizing and others unique parts. The versatile manufacturing capabilities of TRANSCOM’S are capable to meet the needs of developing and producing non-standard solutions in acceptable terms for building or repairment of a catenary.