|

The basic manufacturing processes done by TRANSCOM’S could be sorted as follows: |

Tooling and prototyping For the needs of the manufacturing processes TRANSCOM’S produces its own tooling, such as:

|

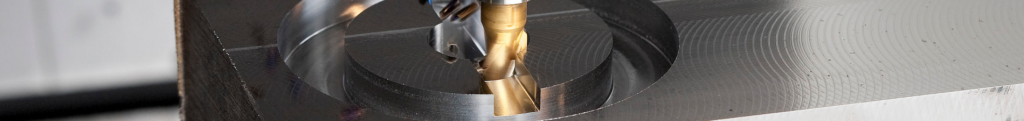

Cold machining TRANSCOM’S have and operates all the machinery needed for machining of casts and conventional metals on the scale of the batch production, including:

|

Casting and heat treatment TRANSCOM’S owns and operates all the machinery for precision casting, die-casting and foam casting, but with the growth scale of production we have learned to cooperate with most of the major foundries in Bulgaria. Our own furnaces include:

|

Rubber and silicone For its pneumatic products TRANSCOM’S uses many different types of nitrile rubbers. In the field of composite silicone insulators the one-component HTV (high temperature vulcanization) material is exclusively delivered by the highest rated suppliers. This material has been proved as the one with the most stable electric-mechanical technical features for dozens of years now. For processing of the material and turning it into finished elements and for assembling of insulators TRANSCOM’S uses the obligatory:

|

Mounting and testing The highly responsible products of TRANSCOM’S require uncompromising inspection at each stage of their manufacturing. For this purpose TRANSCOM’S has built and arranged many test stands and laboratories for pneumatic, electrical and mechanical testing – for both incoming inspection and final testing of the end products – insulators, clamps, fastenings, tensioning wheels etc. This includes:

|

+359 2 832 41 35

info@transcoms.eu